[10/23/22] also see https://luminusdevices.zendesk.com/hc/en-us/articles/10087466808589-Safety-Understanding-IEC-62778-and-Using-KV-B-to-Calculate-White-Light-Eye-Safety-Risk-Groups for more detail.

One question we have seen is: "I have a lower risk group rating for IEC TR 62778 compared to IEC 62471. Can I claim the lower RG?".

The answer is no, you can't.

IEC 62471 is the primary eye safety standard that determines risk over a wide range of tests. IEC 62778 is simply a proposed addendum to IEC 62471 intended to clarify some issues involved in assigning General Lighting Service (GLS) white light source risk groups for the blue light hazard test. GLS sources are defined as white-light sources used to illuminate spaces [1]. If you have a higher RG determination in an IEC 62471 test report compared to the IEC 62778 test report, it is because the highest risk group assignment for that light source was due to a different test than blue light hazard.

IEC 62471 “Photobiological Safety of Lamps and Lamp Systems”: The scope of this standard is to provide guidance for the evaluation of the photobiological safety of lamps and lamp systems, excluding lasers, that emit light in the spectral region 200-3000 nm. When determining the risk group of a light source, the highest risk assessment of all the applicable tests in IEC 62471 is used [2].

This current implementation of IEC 62471 has provided little satisfaction in the lighting industry on a number of points [3]:

- Disagreement over which lamps should be considered in the GLS category (does this include, for example, spotlights or desk lamps?)

- Questions regarding the value of an evaluation at 500 lux, which may not represent a realistic exposure scenario

- Lack of information provided by evaluation at 500 lux, since the majority of sources obtain an exempt risk group classification

- Issues with the implementation of a method to permit the transfer of LED manufacturers' data to finished products.

IEC TR 62778 "Application of IEC 62471 for the assessment of blue light hazard to light sources and luminaires": The scope of this proposed standard is limited to the assessment of the blue light hazard in IEC 62471. Some ambiguities for blue light hazard test conditions for white GLS sources are removed and the concept of KB,v is introduced to relate the blue light eye hazard of white light product lines to correlated color temperature (CCT) and distance (or drive current). This addendum to IEC 62471 is intended to help manufacturers relate component level test results of white LEDs to luminaire risk group ratings by calculating the safe levels for a GLS light source installation in terms of distance from the source, and relating this to CCT vs. lux safe exposure limits.

Risk Groups in IEC 62471. There are four defined risk groups in IEC 62471 which apply to light sources with wavelengths ranging from 200 - 3000 nm. The table below summarizes these risk groups.

| Risk Group | Hazard |

| Exempt | No photobiological hazard |

| RG1 | No photobiological hazard under normal behavioral limitation |

| RG2 | Does not pose a hazard due to aversion response to bright light or thermal discomfort |

| RG3 | Hazardous for even momentary exposure |

To give a sense of scale, the Sun is RG2. Staring at the Sun will result in retinal damage, but no normal person does that. Humans have a natural aversion response that protects our eyes from damage even though we have the Sun in our field of view much of the time when we are outside during the day. Applications such as stage lighting are often RG2. The placement of stage lights and our aversion response protects us from the intense light needed for this application. High-intensity torches are reaching the point where they also might be assigned a RG2 determination.

For GLS (room lighting applications and outdoor applications such as streetlights), RG1 and Exempt are both suitable ratings. Risk group 1 lighting sources might appear a little bright, but the normal movements of the eye and our unconscious aversion response protects us. Risk group 2 is generally too uncomfortable (but not actually dangerous) for office, retail, and outdoor night lighting applications.

Risk group 3 is normally an industrial application (non-GLS use). Non-GLS lamps are measured at 200 mm so there is some safety margin due to real distance factors, but equipment using RG3 light sources should be designed with interlocks to eliminate operator exposure.

IEC 62471 blue light hazard tests. We will describe IEC 62471 blue light hazard testing in simple terms, omitting some complexities.

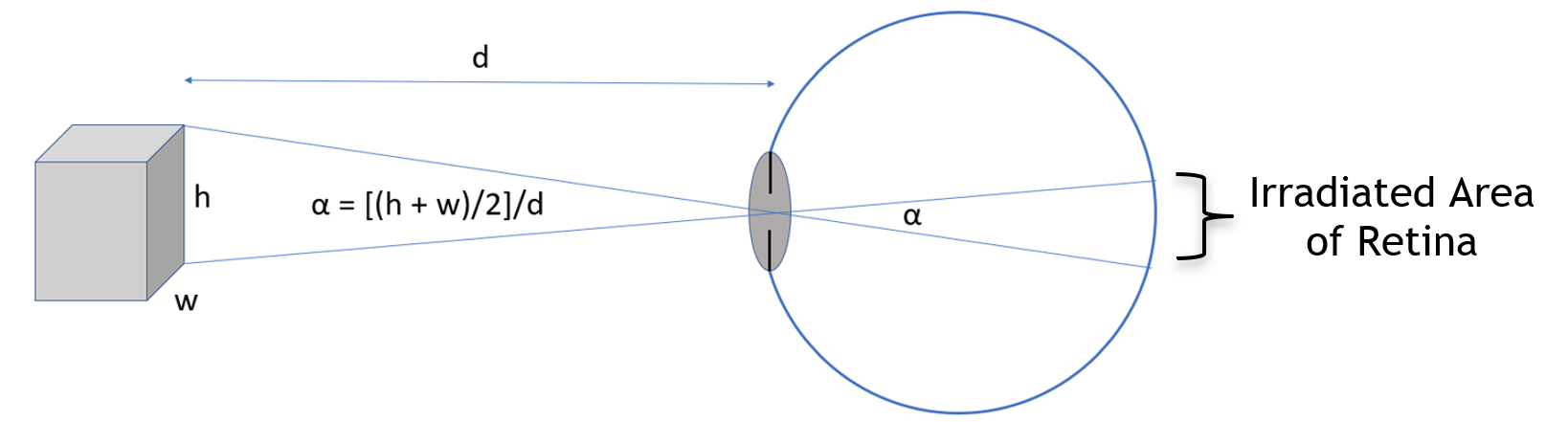

In IEC 62471 the GLS blue light hazard test is conducted at a distance that corresponds to a 500 lux level for each light source and drive condition. Risk group determinations are assigned using the eye acceptance angle, alpha, and either the irradiance or radiance of the light source depending on whether, at the 500 lux distance, the light is a small source or a "normal" source.

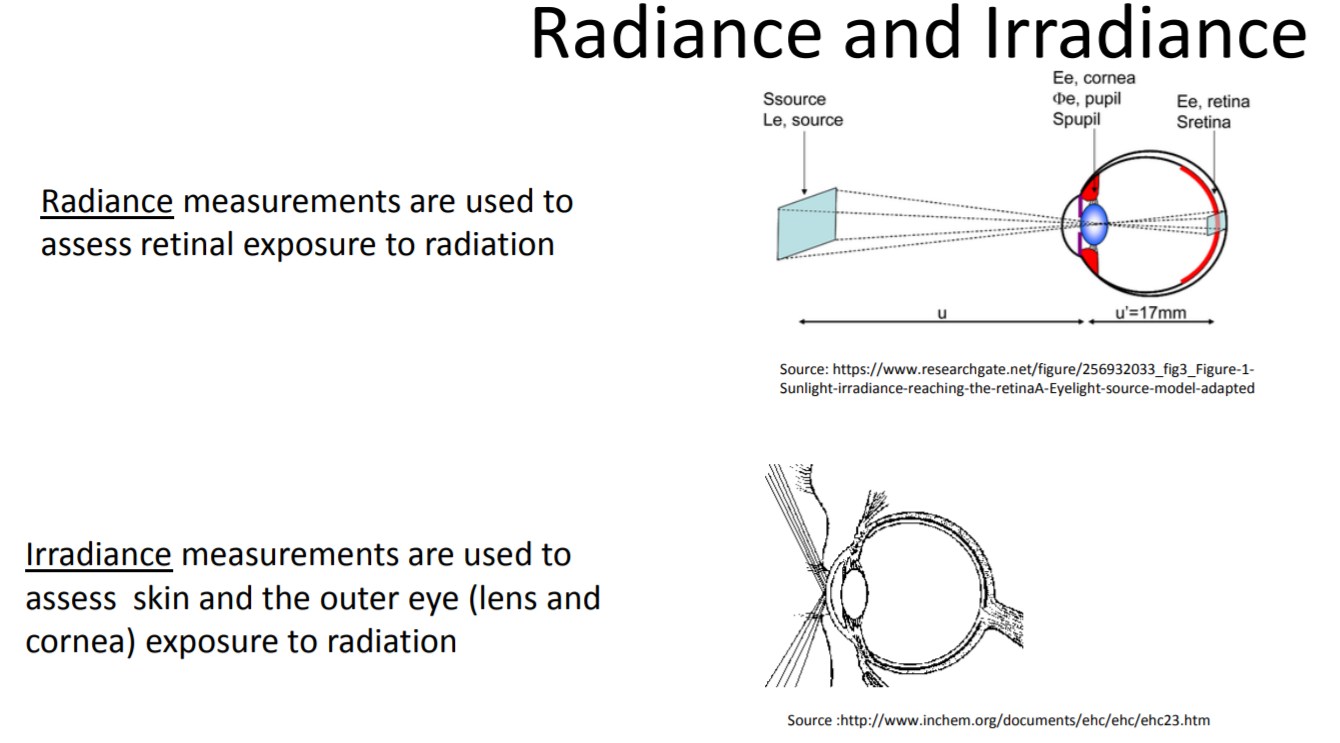

The difference between radiance and irradiance [4]:

- Radiance measurements are used to assess retinal exposure to radiation (top image)

- Irradiance measurements are used to assess skin and the outer eye (lens and cornea) exposure to radiation (bottom image)

The acceptance angle, alpha, is a simple calculation, but there are a number of rules that must be applied if the calculated angle is too small or too large. Once these values and limits have been determined, empirical equations and spectral weighting functions based on physiology are employed to assign a blue light hazard risk group.

The LED drive current conditions are not specified by the standard but, with the variable distance used in this version of the test, the assigned risk group tends to be the same despite different drive currents. If a higher current is used, the distance to achieve 500 lux is increased to accommodate the increase in light from the LED and the only thing that changes is alpha. If alpha gets too small or too large, the acceptance angle limits are applied. The net result is that an RG determination for the blue light hazard of white LEDs over a wide range of drive conditions tends to be the same.

The main problem with this approach for white LED testing is that the correlated color temperature (CCT) effects are not included in the standard. Thus, the LED manufacturer and the test lab have to agree on a mutually acceptable methodology to certify risk groups for high and low CCT LEDs within the same product family.

One approach is to test all variations of parts within a family. This is expensive and time consuming, however, and is not really justified considering the amount of other information available. Another approach is to test the highest CCT part in a group and assign the same risk group to all the lower CCT components in that group. This approach results in the low-CCT parts being miscategorized into a higher risk group than where they really belong (high-CCT LEDs always have significantly more blue light than low-CCT LEDs).

The usual practice is a blend of these two approaches where two LEDs are tested: the highest CCT component and the one in the middle where previous experience suggests the RG1 and exempt boundary will occur. If, for instance, the high-CCT component is RG1 and the middle-CCT component is exempt, we know that all parts with CCT lower than the exempt middle-CCT part are also exempt and all the higher CCT parts must be classified as RG1. If we guess wrong and both CCTs have the same RG, we must perform another test using a lower CCT part.

IEC TR 62778 provides guidance in the assessment of the retinal blue light hazard of all lighting products that emit principally in the visible region, 380–780 nm, and on the transfer of data from LED/lamp to finished products (taking care that the operating conditions are comparable in both cases) [3].

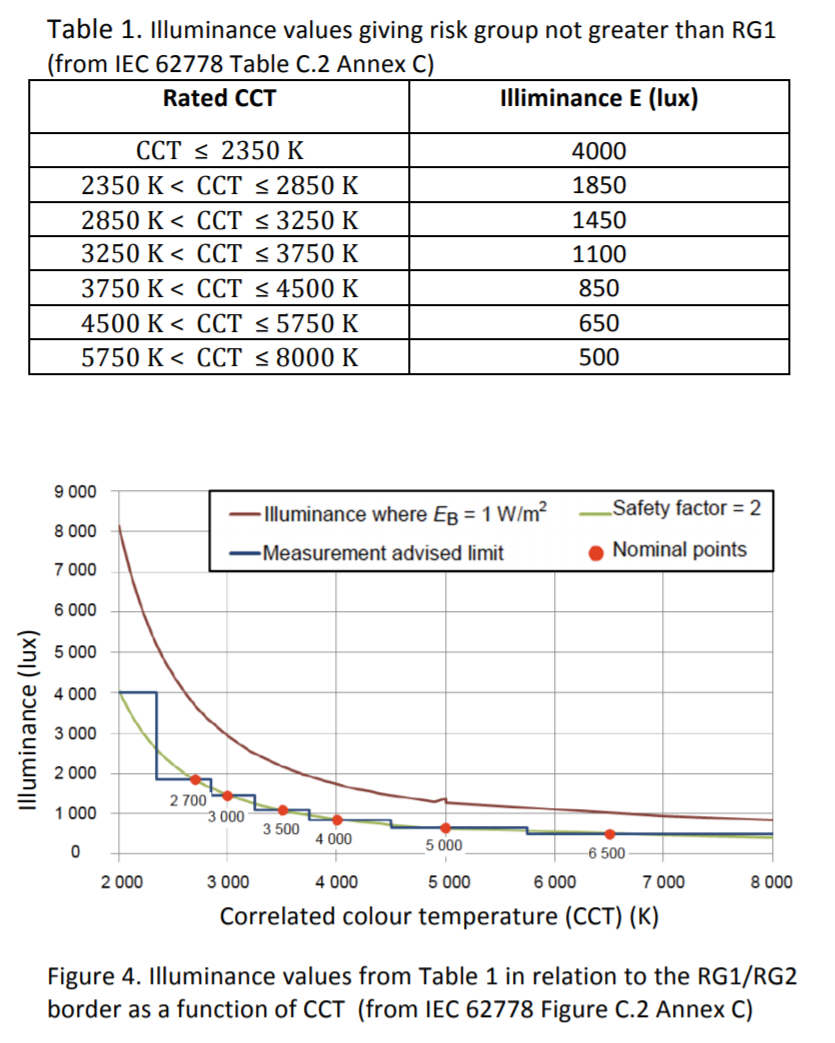

The relationship between CCT and blue light hazard is also discussed. Specifically, the more a source emits light in the blue region, the higher its CCT and the greater the blue light hazard posed. Guidance is provided on the use of source luminance, illuminance, and CCT to determine if a source falls below RG1 threshold values, based on calculation, including a safety factor of two [3].

IEC TR 62778 risk groups are higher IEC 62471 for the same white LED since the distance is much closer compared to the IEC 62471 500 lux method. IEC TR 62778 tests are conducted at a standardized distance of 200 mm (and usually full rated current) and the results for most white power LEDs are RG2 at that distance.

The blue light hazard result from IEC 62471 should be reported until IEC TR 62778 is fully adopted.

So why do we care about IEC TR 62778 if we are getting RG2 results and we can't use them in our product labels? Because it can be used to relate the risk group of installed white light sources and luminaires over a wide range of CCTs, distances, and drive currents. IEC TR 62778 is intended to relate the blue light hazard of a light source under a standard test condition (200 mm distance and full rated current) to conditions where the RG1/RG2 boundary occurs.

This is what luminaire designers really want to know, so when they do their system level tests they can predict the result and their customers can use this information to design safe installations. White LEDs are almost always assigned an IEC 62471 risk group based on the blue light hazard test result; being able to predict results using a standard procedure gives us a huge advantage.

There are two aspects of this analysis: first, determining conditions where the boundary between RG1/RG2 occurs, and second, extending this result to predict the RG1/RG2 boundary for a wide range of CCTs.

The first calculation uses defined values for alpha and a simplified geometric calculation methodology. The measurements are always taken at 200 mm and the new values that are reported are typically the RG1/RG2 distance at full rated current, and the RG1/RG2 current at 200 mm.

The second calculation requires measurement of a few different CCTs at rated current and 200 mm, then using these data to calculate a plot or table that enumerates the CCT vs. installed lux level for the RG1/RG2 boundary. The empirical coefficient KB,v is used in these calculations. The figure below shows one such calculation [5].

[1] "LED-based products must meet photobiological safety standards: part 2", LEDs Magazine, 2011.

[2] "LED-based products must meet photobiological safety standards: part 1", LEDs Magazine, 2011.

[3] "The IEC addresses characterization of the blue light hazard", LEDs Magazine, 2014.

[4] "Are your LED lights safe?", Smart Vision Lights, retrieved 5/14/21.

[5] "LED Lights and Eye Safety Part II: Blue light hazards", Lighting Global, 2015.

Note: LEDs Magazine has an excellent series of articles on eye safety topics.

Related Article

IR-Safety-Considerations-for-Luminus-LEDs

--------------------------------------------------------------------------------------------------------------------

Luminus Website https://www.luminus.com/

Luminus Product Information (datasheets): go to the main page and select Products and then select the type of product you are interested in.

Luminus Design Support (ray files, calculators, ecosystem items: [power supplies, lenses, heatsinks]): go to the main page and select Resources & Tools and select the item you are interested in.

Luminus Product Information sorted by Applications: go to the main page and select Applications.

Where to buy Samples of Luminus LEDs (worldwide): https://www.luminus.com/contact/wheretobuy.

Where to buy Samples of Luminus LEDs (Americas): https://www.luminus.com/contact/wheretobuy/na

--------------------------------------------------------------------------------------------------------------------

Technical Support Contact Information: techsupport@luminus.com

Sales Support Contact Information: sales@luminus.com

Customer Service Support Contact Information: cs@luminus.com

Comments

0 comments

Please sign in to leave a comment.