Current hogging is slang for when a circuit with parallel branch elements does not have the same current in each branch. For LED arrays, this will result in visible stripes of uneven brightness. This can be modeled in Spice and we will present a contrived example below to illustrate the issues.

Spice uses three parameters to define a forward IV diode characteristic. Using Spice nomenclature, these are

-

N - Emission coefficient (also called the ideality factor in other fields)

-

RS - Series resistance

These correspond to the Shockley diode equation (+ a series term) with some caveats. (1) Spice uses numerical methods and there are hidden parameters that aid convergence. (2) Spice parameters that define other diode characteristics (such as pulse response or reverse bias operation) are decoupled and the models are generally simplistic. (3) Spice was developed when silicon and germanium diffused homojunctions and Schottky diodes were the only devices in existence. The default values used in Spice still reflect these types of devices.

The IS and N values used in a model definition determines the diode turn-on voltage level and the shape of the “knee” of the IV curve. The series resistance determines the slope of the IV curve in higher injection.

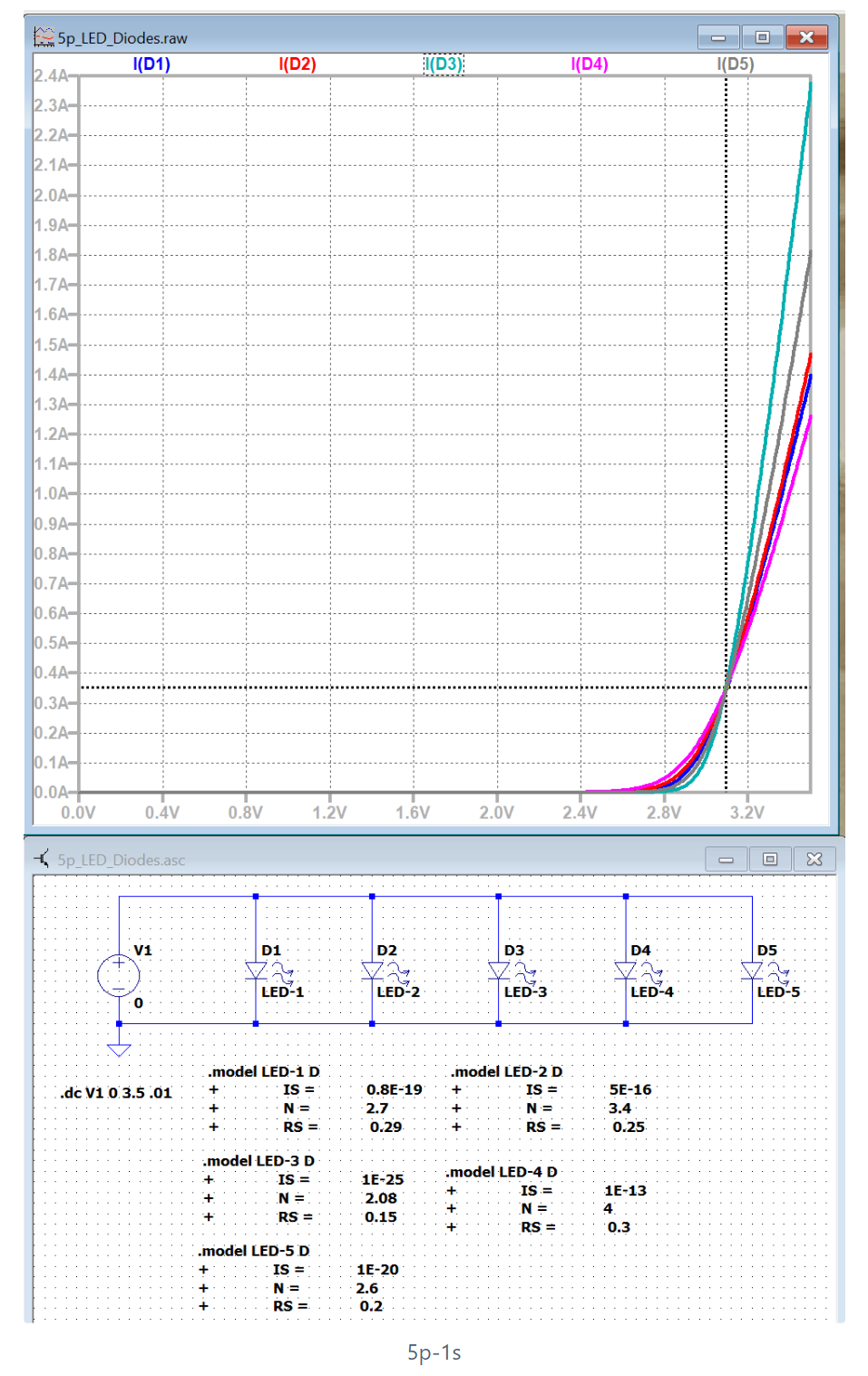

We constructed an arbitrary set of values for five IV curves that intersect at 350 mA to simulate Vf matched parts with variations due to different combinations of IS, N, and RS. Note that modern LEDs can have N values much higher than the absolute n = 1 to 2 range discussed in many solid-state theory texts so seeing larger N values in LED models is not that unusual.

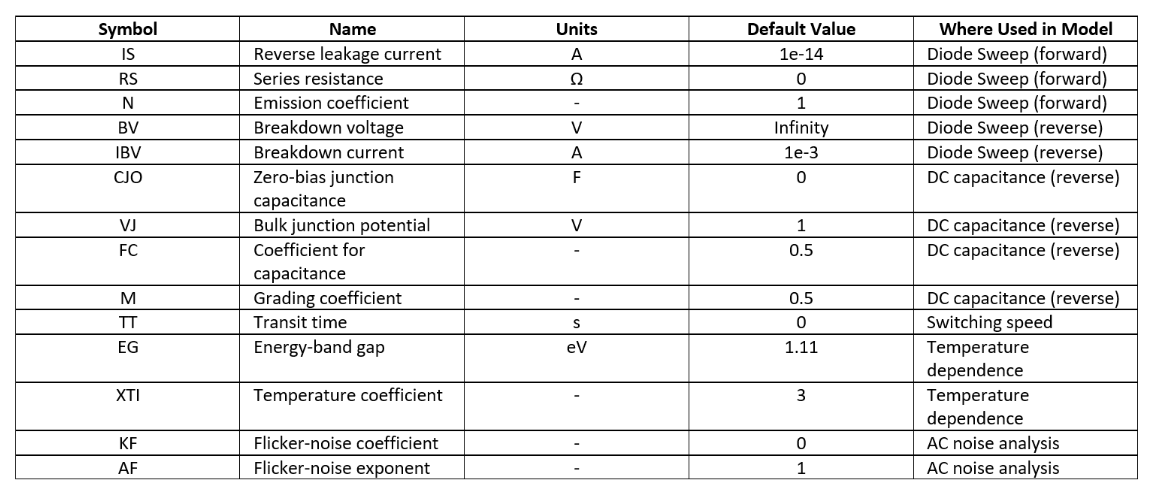

For reference, the most commonly used Spice parameters and default values are shown in the table below. If a Spice model omits a term, the defaults are used.

We start with an LTspice simulation of five voltage matched LEDs (at 350 mA) in a 5p-1s parallel network. The crosshair shows the Vf matching point at 350 mA.

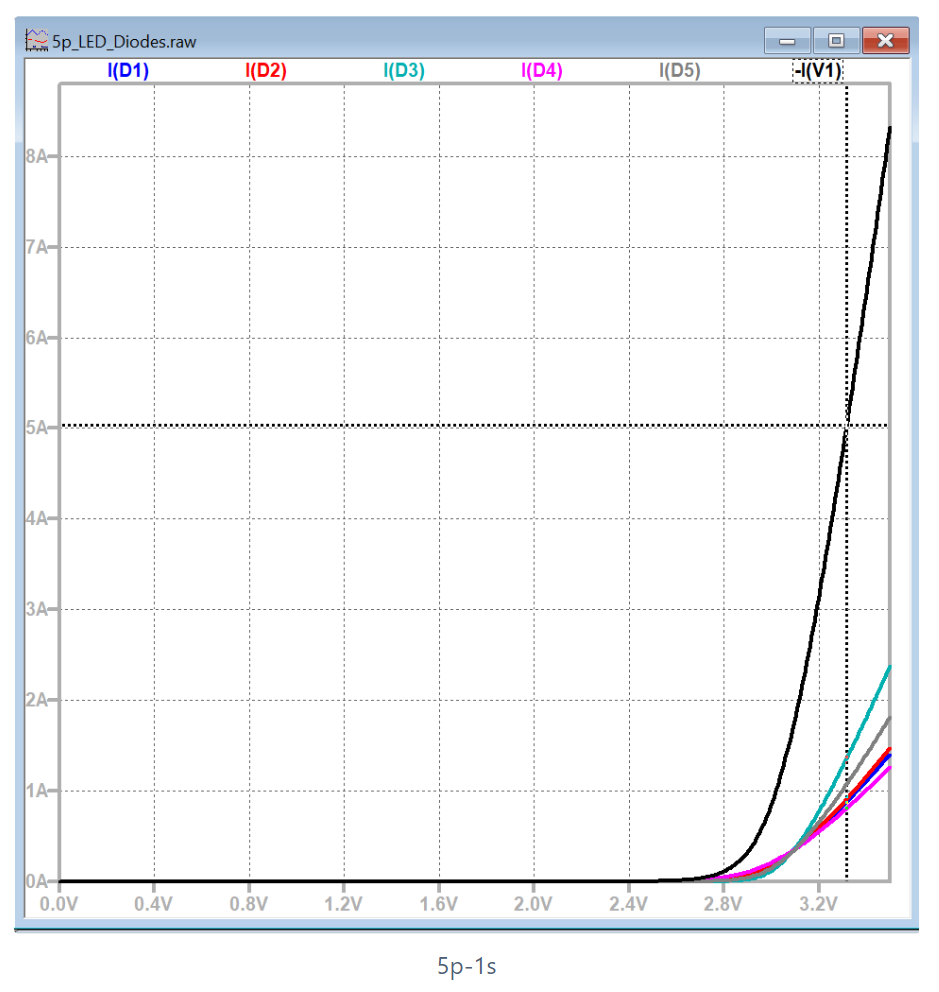

The figure below is the same circuit with the IV curve of the power supply added. The crosshair has been moved to correspond to a 5 A current supplied by the power supply and the vertical line from this point can be used to measure the individual string currents at that bias level. These LEDs have a maximum current of 1.4 A in LED 3 and a minimum of 0.8 A in LED 4 for a current hogging ratio of 1.75.

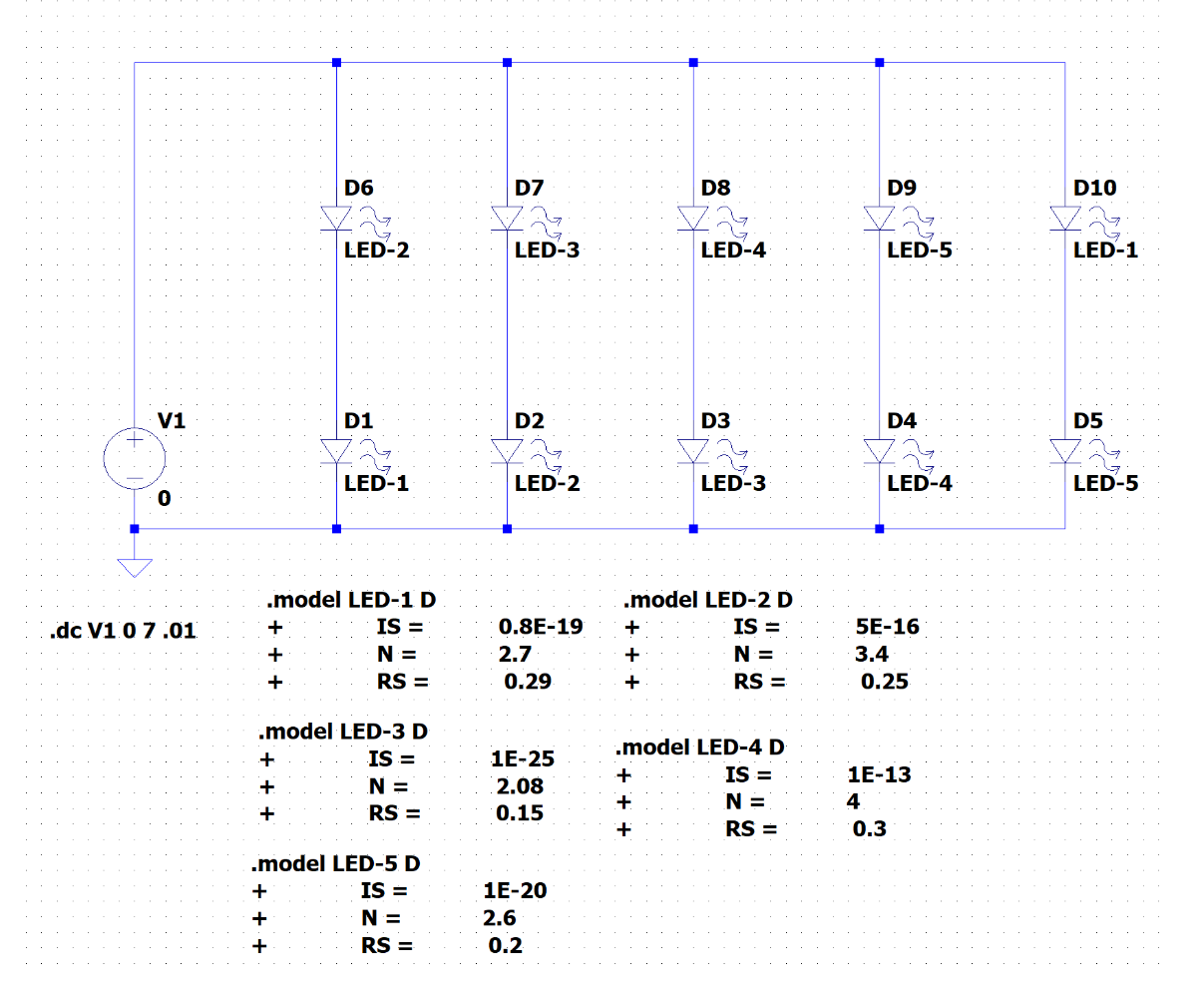

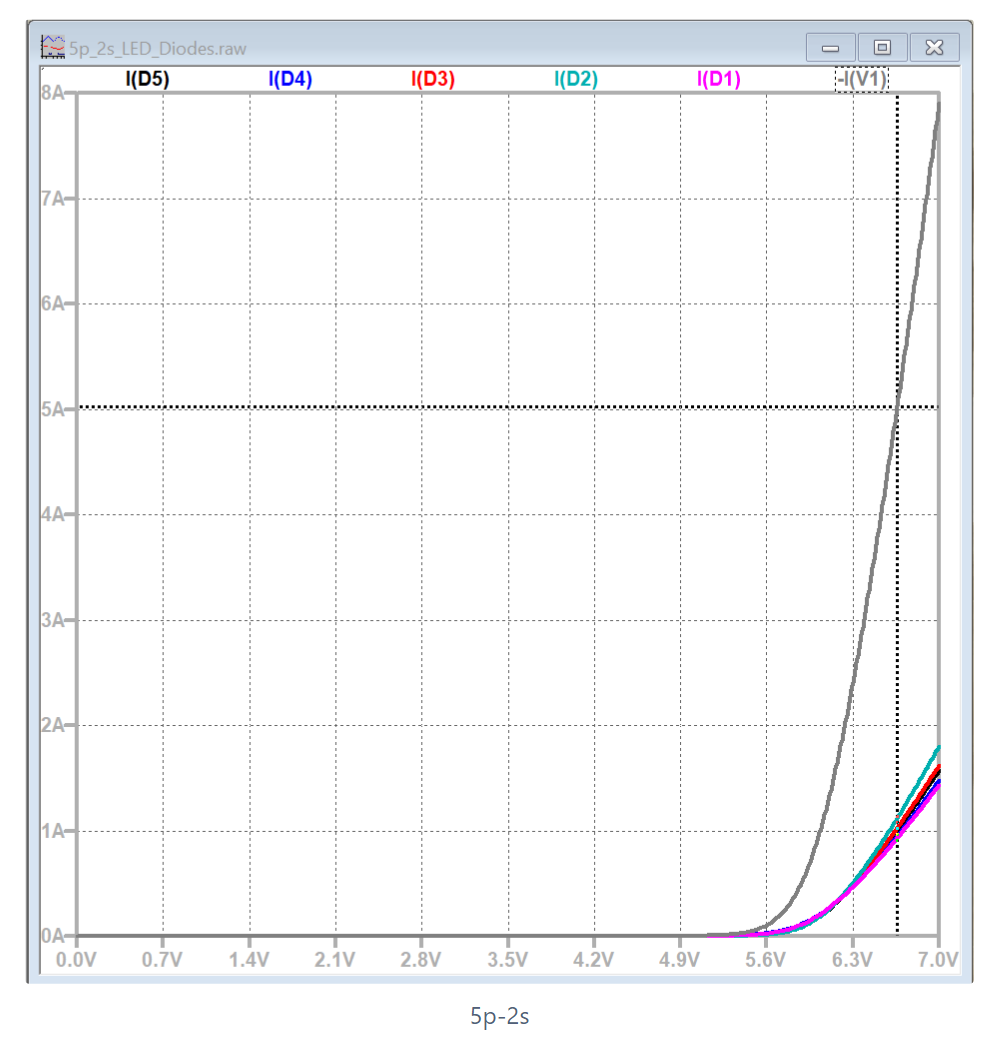

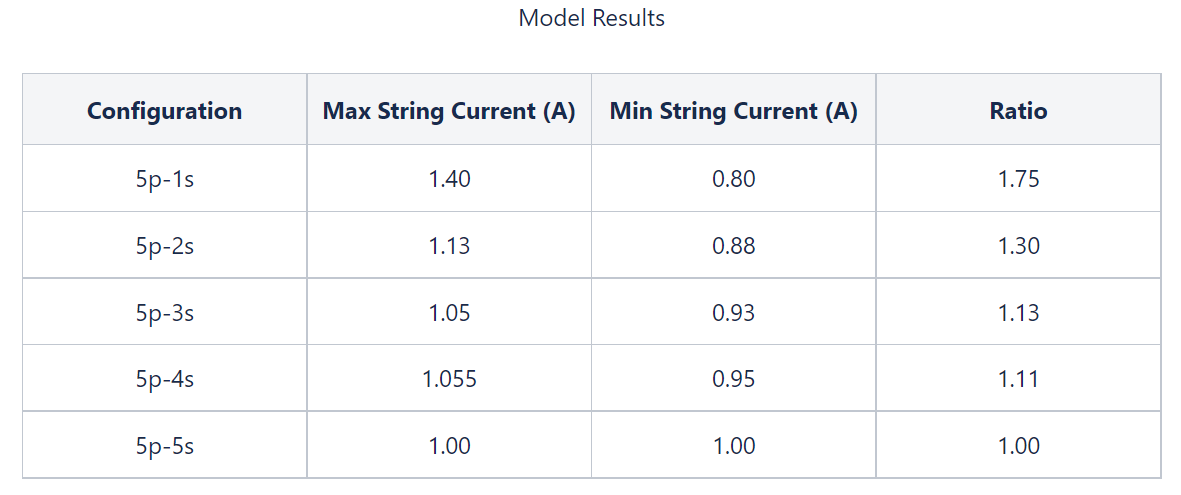

Using series-parallel strings of LEDs significantly reduces current hogging. Below we use two different series LEDs in each parallel current branch by cycling the LED definitions. The current hogging is reduced to 1.13 A max and 0.88 A min (ratio = 1.3).

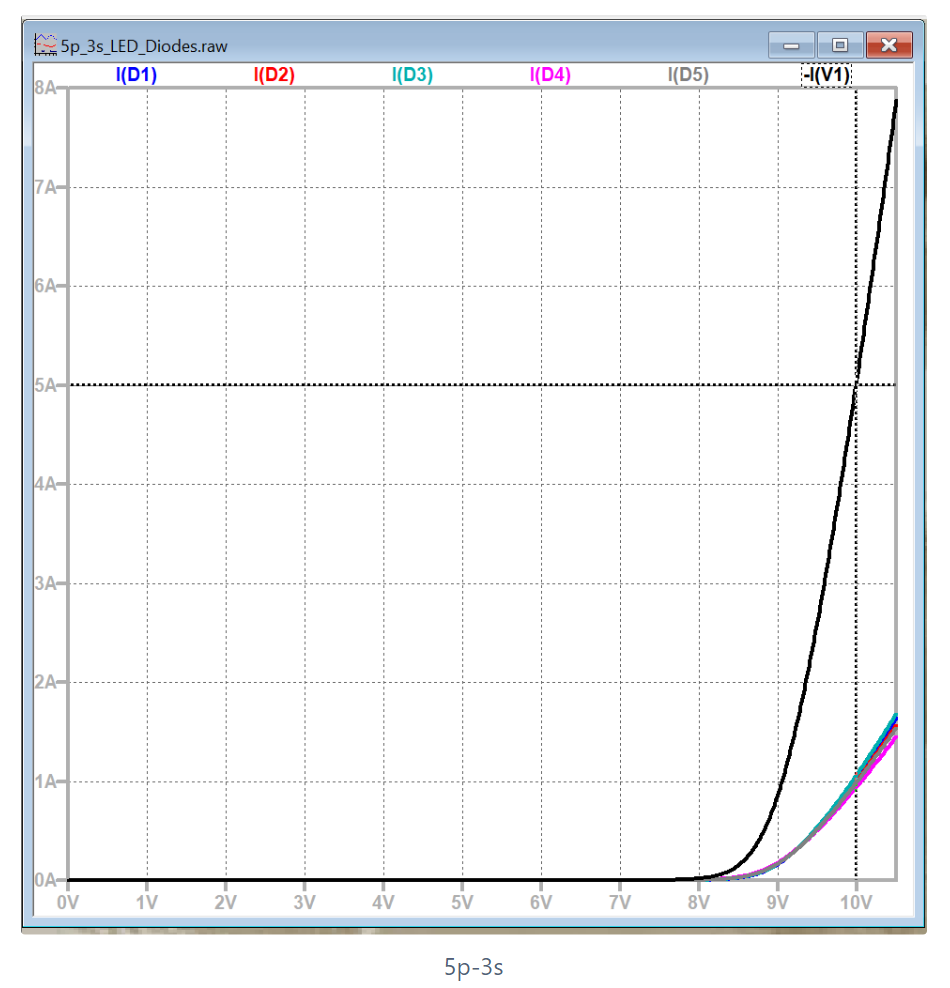

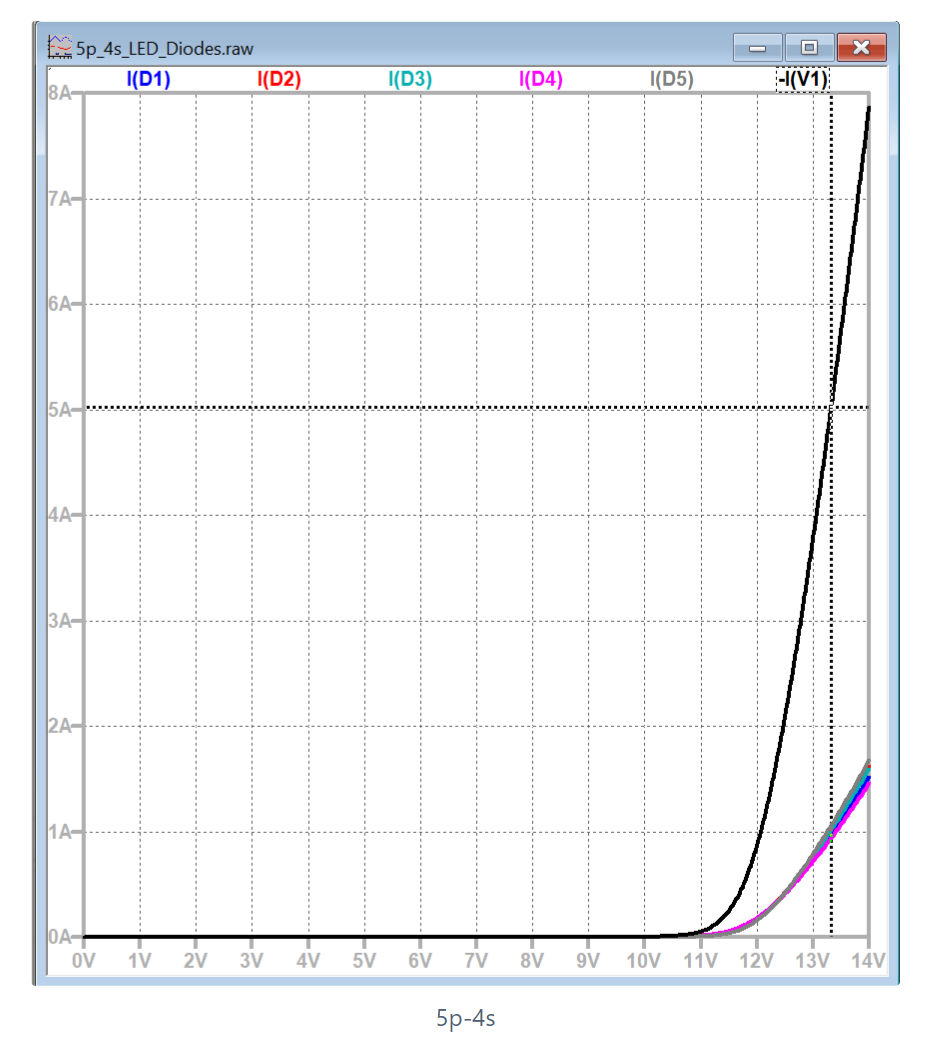

In this contrived example as we continue to add LEDs the current hogging variation goes to zero for

5-LED strings (when all five LED definitions are included in each parallel string).

In reality, each LED has a unique IV characteristic and while current hogging will be reduced by adding series elements to the parallel branches it is unlikely to go to zero. This can be better modeled in Spice using built-in Monte Carlo directives which is beyond the scope of this article.

We provide some recommendations:

-

Never use pure parallel designs. There are also temperature variation issues, not discussed here, that exacerbate problems with pure parallel designs and can cause thermal runaway failures.

-

Always use one Vf bin for series parallel designs and recognize that the binning is done at one point in the IV curve. As the operating point moves away from the test point, IV variations increase. The variations in a single Vf bin are not generally as extreme as in this contrived example. LED color and power binning tend to group similar LEDs together which reduces variation. Note you can use more than one Vf bin in production, just not in the same series parallel network.

-

You can include a sense resistor in your parallel branches if you want to monitor current hogging.

-

Randomness inside an LED reel is a good thing. Measuring and sorting by IV characteristics in your factory is costly and should be avoided. Requesting LED supplier reels be sorted by sequential Vf adds a lot of cost and has no effect on current hogging mitigation. Designing a series parallel network with enough series elements to smooth out current hogging with single bin random placement is the best approach.

-

Consider other criteria to decide which series parallel combination is best for your application.

-

Power supplies have standard current and voltage ratings - you want to select a series parallel network that conforms with your power supply selection.

-

More series elements in a parallel string branch are better but there are limits. Using string voltages that exceed the safety standard that you want to certify against will add cost since mitigation and interlocks may become an added requirement for certification (30 and 50 V are common voltage safety limits). String voltages above 200 V may cause system reliability problems due to inductive and capacitive coupling of external noise while LEDs are floating near their voltage damage threshold.

-

Useful Spice Resources

LTspice Simulator | Analog Devices

LTspice: Adding Third-Party Models | Analog Devices

LTspice Annotated and Expanded Help* - LTwiki-Wiki for LTspice

Simon Bramble | Analog Circuit Design | LTspice Tutorials

Related Luminus Help Center Articles

Electrical – How do I extract Spice IV parameters from an LED datasheet?

Electrical – Can I simulate a set of LED IV curves that have a single Vf bin?

Electrical – Can I calculate LED lumens with Spice?

Electrical - What is Current Hogging in Series Parallel Designs?

Electrical - How do I sweep an LED IV curve in Spice?

Electrical - How do I insert a diode file into LTspice

Electrical - Can I add reference lines to Spice plot panes?

Data Analysis - Using Python to run LTspice as a remote process.

--------------------------------------------------------------------------------------------------------------------

Luminus Website https://www.luminus.com/

Luminus Product Information (datasheets): https://www.luminus.com/products

Luminus Design Support (ray files, calculators, ecosystem items: [power supplies, lenses, heatsinks]): https://www.luminus.com/resources

Luminus Product Information sorted by Applications: https://www.luminus.com/applications

Where to buy Samples of Luminus LEDs: https://www.luminus.com/contact/wheretobuy.

--------------------------------------------------------------------------------------------------------------------

Comments

0 comments

Please sign in to leave a comment.