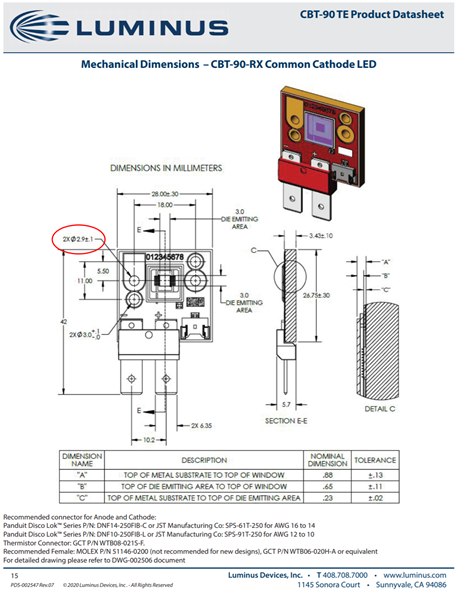

Let’s use the CBT-90-RX as an example. This product has four holes. The design intent is that two are for screws to clamp the LED package to a heatsink and two are for dowel pins to ensure accurate alignment of the LED package in the optical system. The design intent can be identified by the tolerance in this drawing; the 3.0 +0.1/-0.0 mm dowel pin holes have a tighter tolerance than the 2.9 +/- 0.1 mm screw holes. The user can use any combination of holes for screws, but this is the reason the two sets of holes have two different sizes.

What size screw to use?

There are many tables on the internet that have recommended clearance hole diameters. The table below gives an example, and we find that M2.5 is the correct screw size to use for a 2.9 mm clearance hole.

|

Metric Screw Size |

Recommended Clearance Hole Diameter (mm) |

|

M2 |

2.4 |

|

M2.5 |

2.9 |

|

M3 |

3.4 |

What torque to use?

This gets more complicated. The screw torque can be separated into application components:

- The torque needed to overcome thread friction

- The torque needed to ensure that the screw does not loosen over time

- The torque needed to compress the TIM

If you search the internet for recommended torque values, the results are focused on the first two items above. For instance, you might find something like the table below:

|

Metric Screw Size |

Minimum Torque (N-m) |

Maximum Torque (N-m) |

|

M2 |

0.38 |

0.45 |

|

M2.5 |

0.68 |

0.82 |

|

M3 |

1.12 |

1.35 |

These numbers are based on average values for average metal screws and use a criteria related to the tensile strength of the screw to pick values. In the table above, the min-max range is 20% and we can speculate that it is based on 50% of the tensile strength of the screw for the maximum and 30% for the minimum.

For the case of an incompressible TIM such as thermal grease, these numbers are adequate. For cases with compressible TIMs and plastic screws, more analysis in needed. We will show an example for the TIM calculation and leave the plastic screw topic for another article.

We will start with the simple equation for the force applied by a screw:

Where

F = axial screw force

T = wrench torque

K = constant dependent on the screw material and size related to the preload force needed before the applied torque puts stress on the screw body

d = nominal screw diameter

f = friction factor

The TR Fastenings website has a table that provides values for three different types of stainless steel screws and we will use values for an M2.5, A2-70 (type 304) stainless steel screw.

f = 0.3, K = 0.3, d = 0.0025 m, T = 0.75 N-m

then F = 0.75/(0.3*0.0025*(1-0.3)) = 1,429 N

This agrees with the calculator in the Engineering Toolbox.

The A2-70 designation contains tensile strength information. The 70 means that this screw has an ultimate tensile strength of 700 N/mm2. A 2.5 mm screw has a cross-sectional area of 4.91 mm2, so the stress in this screw is 291 N/mm2, 42% of the limit.

Now that we know how to calculate the relation between torque and clamping force of a screw, we will evaluate how much extra torque is needed to compress a TIM before internal stress is transferred to the screw.

We will use the Panasonic “GraphiteTIM (Compressible Type)” PGS with low thermal resistance as an example. These TIMs have design intent maximum pressure of 600 kPa. The area of the CBT-90-RX is

28 x 28 = 784 mm2 and there are two screws involved in clamping down the TIM. Doing some unit conversions,

Force (kN) = Pressure (kPa) * Area (m2)

we find that the total force we need to apply to get 600 kPa is 470 N. Since there are two screws, we use half of this force to calculate how much torque to add to the calculated value above.

Additional Torque (N-m) = 470/2 N * 0.3 * 0.0025 m * (1-0.3) = 0.12 N-m,

so the total recommended torque for this example is 0.75 + 0.12 = 0.87 N-m for each of the two screws.

--------------------------------------------------------------------------------------------------------------------

Luminus Website https://www.luminus.com/

Luminus Product Information (datasheets): https://www.luminus.com/products

Luminus Design Support (ray files, calculators, ecosystem items: [power supplies, lenses, heatsinks]): https://www.luminus.com/resources

Luminus Product Information sorted by Applications: https://www.luminus.com/applications

Where to buy Samples of Luminus LEDs: https://www.luminus.com/contact/wheretobuy.

--------------------------------------------------------------------------------------------------------------------

Technical Support Contact Information: techsupport@luminus.com

Sales Support Contact Information: sales@luminus.com

Customer Service Support Contact Information: cs@luminus.com

Comments

0 comments

Please sign in to leave a comment.