Luminus PT-120 Devices

Luminus High Power Chip on Board devices typically have an electrically connected copper board due to direct chip bonding which ensures better thermal conductivity and a more consistent current flow. For

each specific product, the polarity of core board is described in the product datasheet. Due to this there are several points to keep in mind. The type of screws and how they are pressed in, the thermal interface material between the LED and the heatsink, as well as the connectors to the devices.

Screw Information

Ideally when mounting to a heatsink specific screws are typically recommended. There should be a flat head on the part that's pressing on the coreboard.

The diameter of the head should not be larger than the diameter of the plated area around the hole as to not crush the solder mask. Thread length at minimum should be 1/4th inch.

It is recommended that the devices are mounted onto an electrically isolated heatsink, but in cases where multiple devices are assembled onto a one piece conductive heatsink or when utilizing a common ground design in LED driver we suggest non-conductive screws or plastic sleeves for assembly. Failure of correct connection or electrical isolation might cause part damage or even operator injury due to electrical shock.

For the screw holes, please utilize the proper size as per the product hole sizes in guidance with ANSI/ASME B1.1. In regards to tightening, we recommend that a proper torque is used when assembled. The correct torque applied to the mounting screws may vary among assemblies and applications. For

example, systems subject to vibration or thermal cycling may require higher torque than systems that are not required to withstand such conditions. For this reason a range of torque values is provided. Improper torque can cause warping of the core board leading to insufficient contact with the TIM. For best results the torque applied to the screws should be between 0.104 and 0.208 ft lbs. [0.141 N m to 0.282 N m]

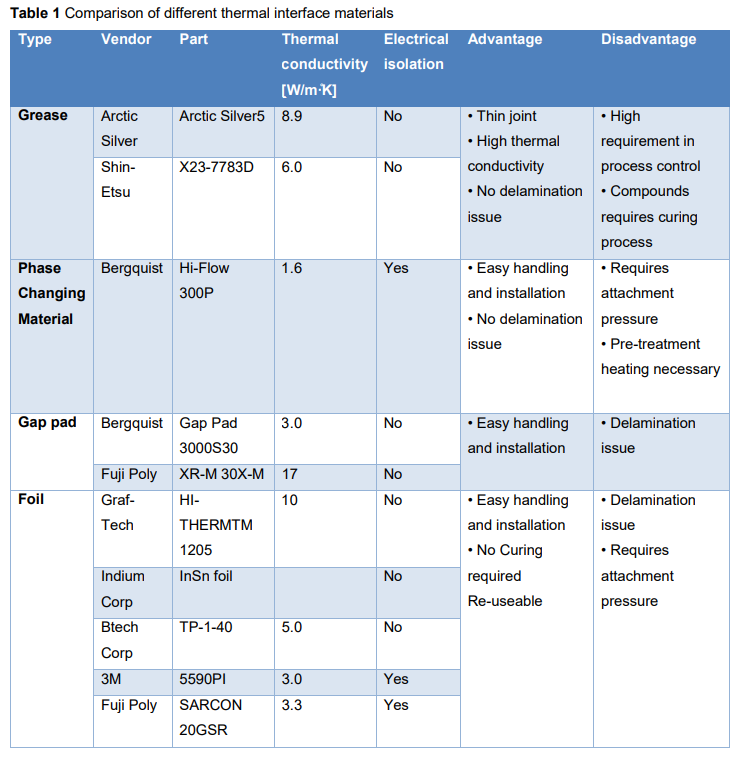

Thermal Interface Material

Due to the heat generated from the devices during operation, Thermal Interface Material (TIM) is typically utilized to ensure a proper thermal path between the copper board and the heatsink underneath. Please see Table 1 in regards to the different types of TIM available and their advantages. Keep in mind that these devices have electrically charged boards. Due to this electrical isolation may also be another key item to consider during the selection of a TIM for your application.

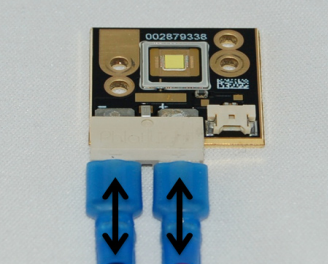

Connector Integrity

Spade connectors are typically utilized for the anode and cathode electrical connections. To maintain the connectors integrity, carefully attaching and detaching disconnects to the connector is important. The connector is soldered onto the core board which can delaminate when forces are applied non parallel to the connector. Force should typically be applied along the same plane as the connectors. It is also suggested that routine disconnects and reconnects are not utilized in application. Several spade connectors have a wearout rate which can range as low as 5-10 mate/unmates depending on the connector technology. Insertion force will also be dependent on the connector technology, as the force needed can be anywhere between 12lbs and 17lbs of force for the first mate.

Force must be applied only parallel to the connector plane

--------------------------------------------------------------------------------------------------------------------

Luminus Website https://www.luminus.com/

Luminus Product Information (datasheets): For Monochromatic datasheets, please click the associated family and generation.

https://www.luminus.com/products/white

https://www.luminus.com/products/uv

https://www.luminus.com/products/color/monochromatic-cob

https://www.luminus.com/products/ir

Luminus Design Support (ray files, calculators, ecosystem items: [power supplies, lenses, heatsinks]): go to the main page and select Resources & Tools and select the item you are interested in.

Luminus Product Information sorted by Applications: go to the main page and select Applications.

Where to buy Samples of Luminus LEDs: https://www.luminus.com/contact/wheretobuy.

--------------------------------------------------------------------------------------------------------------------

Technical Support Contact Information: techsupport@luminus.com

Sales Support Contact Information: sales@luminus.com

Customer Service Support Contact Information: cs@luminus.com

Comments

0 comments

Please sign in to leave a comment.