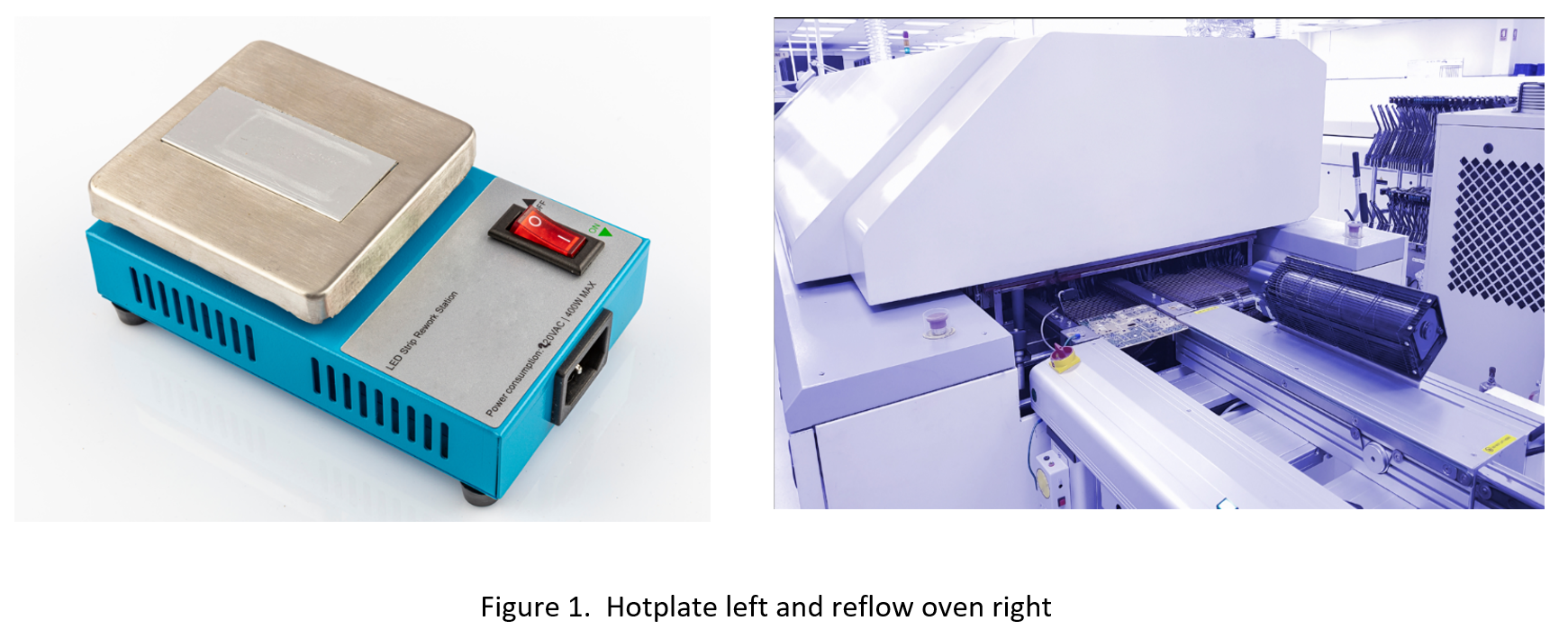

Luminus’ surface mount devices are designed to be reflowed onto a printed circuit board using automated silk screen, pick and place, and a reflow oven to program the correct profile. For rework and prototyping it is possible to use a hotplate and air gun to mount or remove an LED. Using a soldering iron is not recommended because it is difficult to control the temperature of the iron and easy to overheat the LED. Manually mounting and reworking LEDs mounted to printed circuit boards should be done by a trained individual who has experience in correct rework techniques. Proper care not to damage the LED while handling needs to be observed. It is important to note that the lens of an LED should never be touched with tweezers. See Luminus’ application note on soldering and handling for more information.

Below is some basic information when manually soldering surface mount LEDs:

- Use the lowest temperature possible. Depending on the solder utilized, this value will change.

- Pre-stenciling a small amount of solder on the exposed pads is the most accurate way of dispensing solder.

- Do not move devices during ramp-up and ramp-down/solidification.

- A solder iron is not recommended as it is difficult to control the stability of the temperature of an iron.

- Hot plate + hot air gun is preferred to heat uniformly.

- Do not leave the board or device on the hot plate/heat for an extended time. This may damage heat sensitive devices on the board, and may even yellow the solder mask, which can contribute to color inconsistency.

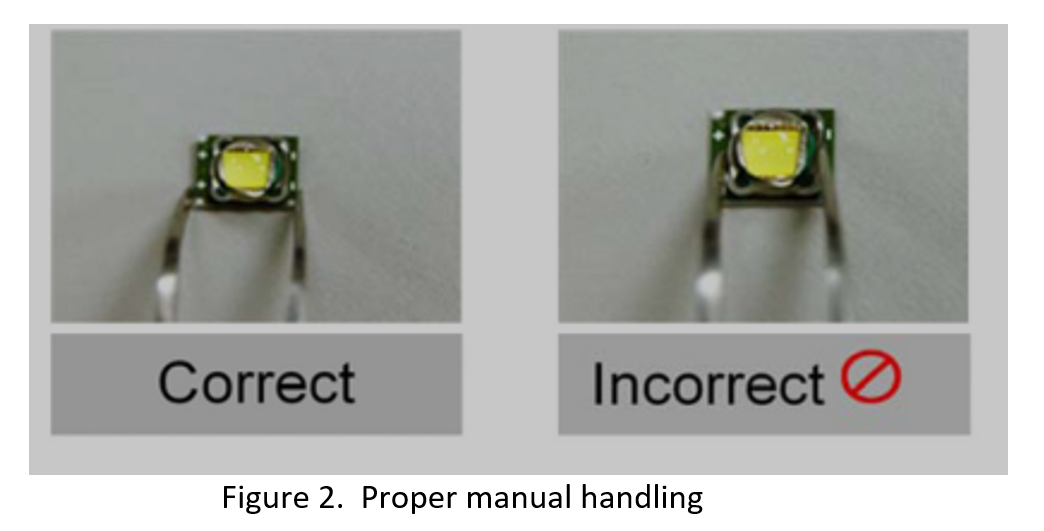

- During handling, make sure not to contact the LES with anything. It is recommended to use tweezers and only pick up the devices by the sides. See Figure 2.

- Never touch the surface of the LED under high temperature. Allow the PCBA to come to room temperature.

- Rework parameters should not exceed the temperatures and soak times listed in the solder manufacture’s datasheet.

- Use a no-clean flux solder paste. If cleaning is required, isopropyl alcohol can be used. Take care not to touch or use any cleaning device on the lens of the LED.

- Follow any moisture sensitivity handling needed for the specific LED that is being used.

- Follow electrostatic discharge procedures to prevent damaging any components sensitive on the printed circuit board. For more information see the individual LED datasheets or the Luminus application note on Electrical Stress Damage to LEDs and How to Prevent It.

Many companies including Hakko, JBC, and Sikama, make a wide variety of rework and prototyping equipment.

References

https://download.luminus.com/datasheets/Luminus_APN_001473_Rev_04.pdf

--------------------------------------------------------------------------------------------------------------------

Luminus Website https://www.luminus.com/

Luminus Product Information (datasheets): https://www.luminus.com/products

Luminus Design Support (ray files, calculators, ecosystem items: [power supplies, lenses, heatsinks]): https://www.luminus.com/resources

Luminus Product Information sorted by Applications: https://www.luminus.com/applications

Where to buy Samples of Luminus LEDs: https://www.luminus.com/contact/wheretobuy.

--------------------------------------------------------------------------------------------------------------------

Comments

0 comments

Please sign in to leave a comment.